পণ্যের বর্ণনা:

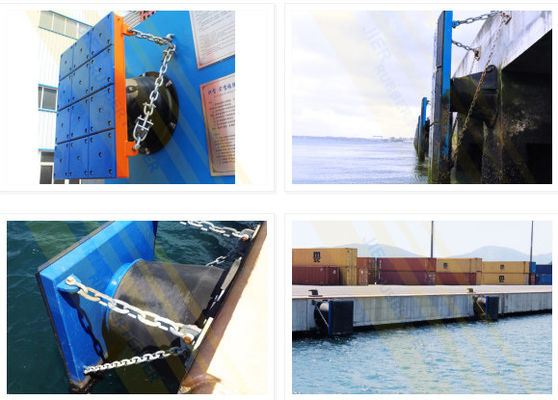

সামুদ্রিক রাবার ফেন্ডারগুলি, বিশেষ করে একটি খিলান আকারে ডিজাইন করা হয়েছে, যা জাহাজ এবং সমুদ্র কাঠামোকে আঘাতের ক্ষতি থেকে রক্ষা করার জন্য একটি শ্রেষ্ঠ সমাধান। এই খিলান-শৈলীর ফেন্ডারগুলি একটি উন্নত এক্সট্রুশন প্রক্রিয়ার মাধ্যমে তৈরি করা হয়, যা কঠিন সমুদ্র পরিবেশে ধারাবাহিক গুণমান, স্থায়িত্ব এবং কর্মক্ষমতা নিশ্চিত করে। তাদের দৃঢ়তা এবং দক্ষতার জন্য পরিচিত, এই ফেন্ডারগুলি YOKOHAMA FENDER নামক একটি নির্ভরযোগ্য ব্র্যান্ডের অধীনে ব্যাপকভাবে স্বীকৃত, যা সামুদ্রিক ফেন্ডার শিল্পের একটি মানদণ্ড।

খিলান-আকৃতির মেরিন রাবার ফেন্ডারগুলির মূল বৈশিষ্ট্যগুলির মধ্যে একটি হল তাদের অনন্য নকশা, যা আঘাতের শক্তিগুলির সর্বোত্তম শোষণ এবং বিতরণের অনুমতি দেয়। খিলান আকারটি একটি বৃহৎ যোগাযোগের পৃষ্ঠের ক্ষেত্র সরবরাহ করে, যা জাহাজের হুল এবং ডক কাঠামোর উপর চাপ কমিয়ে দেয়, যার ফলে বার্থিং অপারেশনের সময় ক্ষতি হ্রাস পায়। এই জ্যামিতিক বিন্যাসটি ফেন্ডারটিকে লোডের অধীনে কার্যকরভাবে সংকুচিত করতে সক্ষম করে, চমৎকার কুশনিং বৈশিষ্ট্য প্রদান করে যা কার্গো জাহাজ, ট্যাঙ্কার এবং যাত্রী ফেরি সহ বিভিন্ন ধরণের জাহাজের জন্য এটিকে আদর্শ করে তোলে।

এই ফেন্ডারগুলির উৎপাদনে ব্যবহৃত এক্সট্রুশন প্রক্রিয়া নিশ্চিত করে যে প্রতিটি ইউনিটের একটি নির্বিঘ্ন এবং অভিন্ন কাঠামো রয়েছে। এই পদ্ধতিতে রাবার উপাদানকে একটি আকৃতির ডাইয়ের মাধ্যমে জোর করে ক্রমাগত খিলান ফেন্ডার তৈরি করা হয় যা পছন্দসই আকারে কাটা যেতে পারে। এক্সট্রুশন কেবল ফেন্ডার জুড়ে ধারাবাহিক বেধ এবং শক্তি নিশ্চিত করে না বরং এর কাঠামোগত অখণ্ডতাও বাড়ায়, যা দীর্ঘ পরিষেবা জীবন এবং কঠোর সমুদ্র পরিস্থিতিতে আরও ভাল পারফরম্যান্সে অবদান রাখে।

মেরিন রাবার ফেন্ডারগুলি আবহাওয়া এবং ক্ষয় প্রতিরোধী হওয়ার জন্য প্রকৌশলী করা হয়েছে, যা সমুদ্র পরিবেশের সবচেয়ে চ্যালেঞ্জিং দুটি কারণ। বিশেষভাবে তৈরি রাবার যৌগ থেকে তৈরি, এই ফেন্ডারগুলি লবণাক্ত জল, UV রশ্মি, চরম তাপমাত্রা এবং অন্যান্য পরিবেশগত চাপের দীর্ঘায়িত এক্সপোজার সহ্য করে উল্লেখযোগ্য অবনতি ছাড়াই। এই আবহাওয়া এবং ক্ষয় প্রতিরোধের ফলে ফেন্ডারগুলির জীবনকাল 8-10 বছর পর্যন্ত বৃদ্ধি পায়, যা দীর্ঘমেয়াদী সমুদ্র অ্যাপ্লিকেশনগুলির জন্য তাদের একটি সাশ্রয়ী এবং নির্ভরযোগ্য পছন্দ করে তোলে।

YOKOHAMA FENDER ব্র্যান্ডটি ফ্লোটিং ফেন্ডার বাজারে গুণমান এবং উদ্ভাবনের সমার্থক। তাদের ফ্লোটিং ফেন্ডারগুলি জাহাজের পাশে ভাসতে ডিজাইন করা হয়েছে, যা ক্রমাগত সুরক্ষা প্রদান করে এবং ডকিং এবং মুরিং অপারেশনের সময় ক্ষতির ঝুঁকি হ্রাস করে। খিলান শৈলীর ফেন্ডার শুধুমাত্র একটি ফ্লোটিং ফেন্ডার হিসাবে কাজ করে না বরং তরঙ্গ এবং জোয়ারের গতির বিরুদ্ধে উন্নত স্থিতিশীলতা এবং স্থিতিস্থাপকতাও প্রদান করে। এই অভিযোজনযোগ্যতা নিশ্চিত করে যে ফেন্ডারটি জলের অবস্থা নির্বিশেষে জাহাজ এবং ডকের সাথে সর্বোত্তম যোগাযোগ বজায় রাখে।

তাদের কার্যকরী সুবিধার পাশাপাশি, এই খিলান-আকৃতির মেরিন রাবার ফেন্ডারগুলি ইনস্টল এবং রক্ষণাবেক্ষণ করা সহজ। তাদের মডুলার ডিজাইন নির্দিষ্ট ডক বা জাহাজের প্রয়োজনীয়তা অনুযায়ী নমনীয় কনফিগারেশনের অনুমতি দেয়। ব্যবহৃত উপকরণগুলির স্থায়িত্বের কারণে রক্ষণাবেক্ষণ সহজ, এবং নিয়মিত পরিদর্শনগুলি নিশ্চিত করতে সাহায্য করে যে ফেন্ডারগুলি তাদের পরিষেবা জীবনকাল জুড়ে কার্যকরভাবে কাজ করে চলেছে। ঘন ঘন প্রতিস্থাপন বা মেরামতের প্রয়োজনীয়তা হ্রাস করা কম পরিচালন খরচ এবং ডাউনটাইম কমিয়ে দেয়।

সংক্ষেপে, এক্সট্রুশন দ্বারা উত্পাদিত খিলান-শৈলীর মেরিন রাবার ফেন্ডারগুলি উদ্ভাবনী নকশা, উচ্চ-মানের উপকরণ এবং প্রমাণিত উত্পাদন কৌশলগুলিকে একত্রিত করে সমুদ্রগামী জাহাজ এবং অবকাঠামোর জন্য শ্রেষ্ঠ সুরক্ষা প্রদান করে। তাদের আবহাওয়া এবং ক্ষয় প্রতিরোধ ক্ষমতা, 8-10 বছরের জীবনকালের সাথে মিলিত, নির্ভরযোগ্য এবং সাশ্রয়ী ফেন্ডার সমাধান খুঁজছেন এমন সমুদ্র অপারেটরদের জন্য তাদের একটি চমৎকার বিনিয়োগ করে তোলে। ফ্লোটিং ফেন্ডার প্রযুক্তিতে একজন নেতা হিসাবে YOKOHAMA FENDER-এর খ্যাতি বিশ্বব্যাপী সমুদ্র সম্পদ রক্ষায় এই পণ্যগুলির মূল্য এবং কর্মক্ষমতাকে আরও জোরদার করে।

বৈশিষ্ট্য:

-

পণ্যের নাম: মেরিন রাবার ফেন্ডার

-

প্রকার: ফ্লোটিং ফেন্ডার, নিউমেটিক রাবার ফেন্ডার

-

শৈলী: খিলান

-

রঙ: কালো

-

রক্ষণাবেক্ষণ: কম রক্ষণাবেক্ষণ

-

ডিজাইন ব্যবহার জীবন: 10 বছর

-

আইটেম নং: সুপার আর্চ রাবার ফেন্ডার

প্রযুক্তিগত পরামিতি:

|

আকৃতি

|

খিলান

|

|

প্রক্রিয়া

|

এক্সট্রুশন

|

|

কম্প্রেশন কর্মক্ষমতা

|

চমৎকার

|

|

প্যাকিং

|

স্বাভাবিক প্যাকিং

|

|

আবেদন

|

বিভিন্ন সমুদ্র পরিবেশের জন্য উপযুক্ত

|

|

আইটেম নং

|

সুপার আর্চ রাবার ফেন্ডার

|

|

স্থিতিস্থাপকতা

|

উচ্চ

|

|

জীবনকাল

|

8-10 বছর

|

|

রঙ

|

কালো

|

|

প্রযুক্তি

|

উচ্চ চাপ

|

অ্যাপ্লিকেশন:

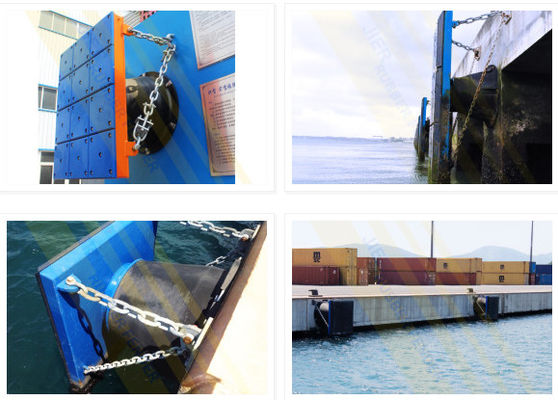

XINCHENG মেরিন রাবার ফেন্ডারগুলি, বিশেষ করে সুপার আর্চ রাবার ফেন্ডার মডেল, বিভিন্ন সমুদ্র পরিবেশে শ্রেষ্ঠ সুরক্ষা এবং স্থায়িত্ব প্রদানের জন্য ডিজাইন করা হয়েছে। কিংডাওতে উৎপাদিত, এই ফেন্ডারগুলি জাহাজ থেকে জাহাজে স্থানান্তর, জাহাজ থেকে ডক মুরিং এবং বন্দর সুরক্ষার জন্য আদর্শ। তাদের চমৎকার কম্প্রেশন কর্মক্ষমতা নিশ্চিত করে যে জাহাজগুলি আঘাতের ক্ষতি থেকে সুরক্ষিত থাকে, যা তাদের সমুদ্র ক্রিয়াকলাপে একটি অপরিহার্য উপাদান করে তোলে।

XINCHENG মেরিন রাবার ফেন্ডারগুলির মূল অ্যাপ্লিকেশনগুলির মধ্যে একটি হল ব্যস্ত বন্দর এবং পোতাশ্রয়গুলিতে যেখানে জাহাজগুলি ঘন ঘন ডক করে এবং আনডক করে। ফেন্ডারগুলি বার্থিং জাহাজ থেকে গতিশক্তি শোষণ করে, জাহাজ এবং ডক অবকাঠামো উভয় ক্ষেত্রেই ক্ষতি কমায়। তাদের বার্ধক্য প্রতিরোধের বৈশিষ্ট্যের কারণে, এই ফেন্ডারগুলি লবণাক্ত জল, UV রশ্মি এবং বিভিন্ন তাপমাত্রা সহ কঠোর সমুদ্র অবস্থার সংস্পর্শে আসার দীর্ঘ সময় ধরে সর্বোত্তম কর্মক্ষমতা বজায় রাখে।

ঐতিহ্যবাহী সমুদ্র সেটিংসের পাশাপাশি, এই ফেন্ডারগুলি অফশোর প্ল্যাটফর্ম এবং শিপইয়ার্ডগুলির জন্যও অত্যন্ত উপযুক্ত যেখানে ভারী-শুল্ক সুরক্ষা প্রয়োজন। তাদের শক্তিশালী নির্মাণ তাদের ফ্লোটিং ফেন্ডার হিসাবে কার্যকরভাবে কাজ করতে দেয়, কুশনিং প্রদান করে এবং ভাসমান কাঠামো এবং জাহাজের নিরাপত্তা নিশ্চিত করে। XINCHENG সুপার আর্চ রাবার ফেন্ডার নির্দিষ্ট আকার এবং কর্মক্ষমতা প্রয়োজনীয়তা মেটাতে কাস্টমাইজ করা যেতে পারে, যা তাদের অনন্য সমুদ্র পরিস্থিতিতে মানানসই করে তোলে।

XINCHENG মেরিন রাবার ফেন্ডারগুলি YOKOHAMA FENDER, নিউমেটিক রাবার ফেন্ডার এবং ফ্লোটিং ফেন্ডারের মতো অন্যান্য ধরণের মেরিন ফেন্ডারের পরিপূরক, যা বিভিন্ন অপারেশনাল প্রয়োজনের জন্য বহুমুখী সমাধান প্রদান করে। যেখানে YOKOHAMA FENDERগুলি তাদের নির্ভরযোগ্যতার জন্য সুপরিচিত, সেখানে XINCHENG ফেন্ডারগুলি তাদের শ্রেষ্ঠ বার্ধক্য প্রতিরোধ ক্ষমতা এবং চমৎকার কম্প্রেশন কর্মক্ষমতা দিয়ে আলাদা, যা তাদের অনেক সমুদ্র অ্যাপ্লিকেশনের জন্য একটি পছন্দের পছন্দ করে তোলে।

ফেন্ডারগুলি তাদের গন্তব্যে অক্ষত অবস্থায় এবং অবিলম্বে ব্যবহারের জন্য প্রস্তুত হওয়ার জন্য স্বাভাবিক প্যাকিং মানগুলির অধীনে যত্ন সহকারে পরিচালনা করা হয়। নতুন ইনস্টলেশন বা বিদ্যমান ফেন্ডারগুলির প্রতিস্থাপনের জন্য হোক না কেন, XINCHENG সুপার আর্চ রাবার ফেন্ডার বিভিন্ন সমুদ্র পরিবেশের জন্য উপযুক্ত একটি নির্ভরযোগ্য বিকল্প, যা বিশ্বব্যাপী সমুদ্র ক্রিয়াকলাপে নিরাপত্তা এবং অপারেশনাল দক্ষতা বৃদ্ধি করে।

কাস্টমাইজেশন:

XINCHENG আপনার নির্দিষ্ট চাহিদা মেটাতে ডিজাইন করা কাস্টমাইজযোগ্য মেরিন রাবার ফেন্ডার সরবরাহ করে। আমাদের ফ্লোটিং ফেন্ডার পণ্যগুলি জনপ্রিয় আর্চ শৈলী সহ বিভিন্ন শৈলীতে তৈরি করা যেতে পারে, যা সর্বোত্তম কর্মক্ষমতা এবং স্থায়িত্ব নিশ্চিত করে। উন্নত এক্সট্রুশন প্রক্রিয়া ব্যবহার করে কিংডাওতে উৎপাদিত, এই ফেন্ডারগুলি চমৎকার বার্ধক্য প্রতিরোধ ক্ষমতা এবং 8-10 বছরের দীর্ঘ জীবনকাল প্রদান করে, যা তাদের সমুদ্র অ্যাপ্লিকেশনগুলির জন্য একটি নির্ভরযোগ্য পছন্দ করে তোলে। আপনার একটি স্ট্যান্ডার্ড ফ্লোটিং ফেন্ডার বা একটি বিশেষ YOKOHAMA FENDER প্রয়োজন হোক না কেন, আমরা আপনার প্রয়োজনীয়তা অনুযায়ী মডেল নম্বর এবং প্যাকিং কাস্টমাইজ করতে পারি, স্বাভাবিক প্যাকিং স্ট্যান্ডার্ড বিকল্প হিসাবে। উচ্চ-মানের, কাস্টমাইজড মেরিন ফেন্ডারগুলির জন্য XINCHENG-এর উপর আস্থা রাখুন যা আপনার জাহাজগুলিকে কার্যকরভাবে রক্ষা করে।

সমর্থন এবং পরিষেবা:

আমাদের মেরিন রাবার ফেন্ডারগুলি বিভিন্ন সমুদ্র অ্যাপ্লিকেশনের জন্য শ্রেষ্ঠ সুরক্ষা এবং স্থায়িত্ব প্রদানের জন্য ডিজাইন করা হয়েছে। সর্বোত্তম কর্মক্ষমতা এবং দীর্ঘায়ু নিশ্চিত করতে, ইনস্টলেশন, রক্ষণাবেক্ষণ এবং পরিদর্শনের জন্য প্রস্তাবিত নির্দেশিকাগুলি অনুসরণ করা গুরুত্বপূর্ণ।

ইনস্টলেশন: মেরিন রাবার ফেন্ডারগুলির কার্যকারিতার জন্য সঠিক ইনস্টলেশন অত্যন্ত গুরুত্বপূর্ণ। উপযুক্ত ফিটিং এবং হার্ডওয়্যার ব্যবহার করে ফেন্ডারগুলি জাহাজ বা ডক কাঠামোর সাথে নিরাপদে মাউন্ট করা হয়েছে তা নিশ্চিত করুন। অতিরিক্ত-টাইট করা এড়িয়ে চলুন, যা ফেন্ডারের বিকৃতি বা ক্ষতির কারণ হতে পারে।

রক্ষণাবেক্ষণ: নিয়মিত রক্ষণাবেক্ষণ মেরিন রাবার ফেন্ডারগুলির জীবনকাল বাড়াতে সাহায্য করে। লবণ, ময়লা এবং ধ্বংসাবশেষ অপসারণ করতে পর্যায়ক্রমে তাজা জল দিয়ে ফেন্ডারগুলি পরিষ্কার করুন। পরিধান, কাটা বা ঘর্ষণের কোনো লক্ষণের জন্য পরিদর্শন করুন। UV রশ্মি এবং কঠোর সমুদ্র পরিবেশের বিরুদ্ধে প্রতিরোধ ক্ষমতা বাড়ানোর জন্য প্রস্তুতকারকের দ্বারা প্রস্তাবিত হলে প্রতিরক্ষামূলক আবরণ প্রয়োগ করুন।

পরিদর্শন: ফেন্ডারগুলির অবস্থা নিরীক্ষণের জন্য নিয়মিত পরিদর্শন করুন। স্থিতিস্থাপকতা হ্রাস, ফাটল বা স্থায়ী বিকৃতির জন্য পরীক্ষা করুন। নিরাপত্তা এবং কর্মক্ষমতা মান বজায় রাখতে ক্ষতিগ্রস্ত বা অতিরিক্ত পরিধান করা ফেন্ডারগুলি অবিলম্বে প্রতিস্থাপন করুন।

প্রযুক্তিগত সহায়তা: পণ্যের স্পেসিফিকেশন, ইনস্টলেশন নির্দেশিকা বা সমস্যা সমাধানের বিষয়ে প্রযুক্তিগত সহায়তার জন্য, অনুগ্রহ করে পণ্য ম্যানুয়াল বা প্রযুক্তিগত ডেটাশিট দেখুন। আপনার মেরিন রাবার ফেন্ডারগুলি তাদের উদ্দেশ্যে কার্যকরভাবে কাজ করে তা নিশ্চিত করার জন্য আমাদের সহায়তা দল বিশেষজ্ঞ পরামর্শ দিতে উপলব্ধ।

পরিষেবা: আমরা নির্দিষ্ট প্রকল্পের প্রয়োজনীয়তা মেটাতে কাস্টমাইজেশন বিকল্পগুলি অফার করি, যার মধ্যে বিভিন্ন আকার, আকার এবং উপাদান যৌগ অন্তর্ভুক্ত রয়েছে। অতিরিক্তভাবে, আমরা আপনার ফেন্ডার সিস্টেমগুলিকে সর্বোত্তম অবস্থায় বজায় রাখতে সাহায্য করার জন্য অন-সাইট পরিদর্শন এবং রক্ষণাবেক্ষণ পরিষেবা সরবরাহ করি।

প্যাকিং এবং শিপিং:

আমাদের মেরিন রাবার ফেন্ডারগুলি পরিবহনের সময় সর্বাধিক সুরক্ষা নিশ্চিত করার জন্য সাবধানে প্যাকেজ করা হয়। প্রতিটি ফেন্ডার পৃষ্ঠের ক্ষতি এবং ক্ষয় রোধ করতে টেকসই প্লাস্টিক ফিল্মে মোড়ানো হয়। ফেন্ডারগুলি তারপরে কাঠের প্যালেটে নিরাপদে স্থাপন করা হয়, অতিরিক্ত প্যাডিং উপকরণগুলি আন্দোলন এবং প্রভাব কমাতে ব্যবহৃত হয়।

শিপিংয়ের জন্য, আমরা অর্ডারের আকার এবং পরিমাণের উপর নির্ভর করে শক্তিশালী কাঠের ক্রেট বা শক্তিশালী কন্টেইনার ব্যবহার করি। সমস্ত প্যাকেজগুলি নিরাপদ এবং দক্ষ ডেলিভারি নিশ্চিত করতে হ্যান্ডলিং নির্দেশাবলী এবং পণ্যের বিবরণ দিয়ে স্পষ্টভাবে লেবেল করা হয়। আমরা বিশ্বব্যাপী আমাদের গ্রাহকদের চাহিদা মেটাতে সমুদ্র মালবাহী, বিমান মালবাহী এবং এক্সপ্রেস কুরিয়ার পরিষেবা সহ একাধিক শিপিং বিকল্প অফার করি।

শিপিং প্রক্রিয়া জুড়ে, আমরা নিশ্চিত করি যে মেরিন রাবার ফেন্ডারগুলি তাদের গন্তব্যে নিখুঁত অবস্থায় আসে, অবিলম্বে ইনস্টলেশন এবং ব্যবহারের জন্য প্রস্তুত।

FAQ:

Q1: কোন ব্র্যান্ড মেরিন রাবার ফেন্ডার তৈরি করে?

A1: মেরিন রাবার ফেন্ডারগুলি XINCHENG ব্র্যান্ড দ্বারা তৈরি করা হয়।

Q2: মেরিন রাবার ফেন্ডারগুলির মডেল নম্বর কাস্টমাইজ করা যাবে?

A2: হ্যাঁ, মেরিন রাবার ফেন্ডারগুলির মডেল নম্বর আপনার নির্দিষ্ট প্রয়োজনীয়তা অনুযায়ী কাস্টমাইজ করা যেতে পারে।

Q3: XINCHENG মেরিন রাবার ফেন্ডারগুলি কোথায় উত্পাদিত হয়?

A3: এই মেরিন রাবার ফেন্ডারগুলি চীনের কিংডাওতে উত্পাদিত হয়।

Q4: XINCHENG মেরিন রাবার ফেন্ডার ব্যবহার করার জন্য কোন ধরণের সমুদ্রগামী জাহাজ উপযুক্ত?

A4: XINCHENG মেরিন রাবার ফেন্ডারগুলি জাহাজ, নৌকা, ডক এবং পিয়ার সহ বিভিন্ন ধরণের সমুদ্রগামী জাহাজের জন্য উপযুক্ত যা আঘাতের ক্ষতি থেকে রক্ষা করে।

Q5: XINCHENG মেরিন রাবার ফেন্ডারগুলির নির্মাণে কোন উপকরণ ব্যবহার করা হয়?

A5: ফেন্ডারগুলি উচ্চ-মানের রাবার উপকরণ থেকে তৈরি করা হয় যা সমুদ্র পরিবেশে চমৎকার স্থায়িত্ব এবং প্রভাব শোষণ সরবরাহ করার জন্য ডিজাইন করা হয়েছে।

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!